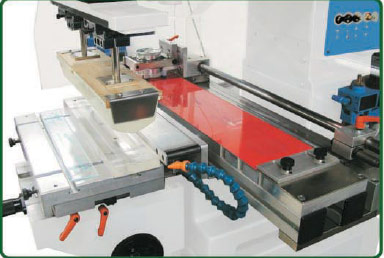

KIPP200-IDS

Features

- Single or multi color user-friendly automatic pad printer

- Big machine stand for steady industrial use

- Pneumatic pad carriage and up/ down

(Servo pad carriage optional) - Heavy gage steel construction machine structure

- Auto pad clean (72 mm tape) (on ink cup model only)

- Use sealed ink cup or open ink tray set up

- Compatible with long life, economy of Green plate,

10 mm steel plate, thin steel plate and polymer plate - Dead-on printing plate registration for quick job change

- Microprocessor with membrane switch control panel

- Special functions: double ink/ print cycles, dwell,

delay before print - Digital pad stroke (DPS) for variable printing depth

- Safety cover

- Hardened, precision ground steel shaft with impregnated bushing ensure friction-free movement

- High speed, smooth machine movement

-

Ink cup size (diameter) :

90, 130, 150 mm

-

Ink cup/ Plate size :

100 X 250, 150 X 300,

-

180 x 350 mm

-

Ink tray/ Plate size :

200 x 150 mm -650 mm

-

Max. speed: (dry cycle)

1,000 Cycles/ Hr.

-

Max. pad pressure :

3,016N at 6 Bar

-

Power :

110/220V 50/60Hz SOW

-

Air consumption :

400 Litre/ Min. (Approx.)

-

Size (L x W x H) :

1,200 x 1,000 x 1,750 mm

-

Weight :

430 Kg (Approx.)

-

Powerful print for big image on big product

-

Servo drive pad carriage

-

Pneumatic shuttle (2 color)

-

Conveyor (4 - 6 color)

-

Digital shuttle for multi-color (DRE-700)

-

Side way ink cup for long image printing (SCMIC)

*Please note that actual output may be affected by print requirement, ink drying condition, load,unload arrangement, pad stroke speed, pad hardness, production setup, product quality and production control.