PP150-IDS

Features

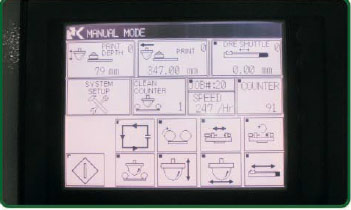

- ????????? ????????????

- ??????????????????????? ??

- ???????????

- ???? ???????

- ?????????????10????????????

- ??????????????????

- PLC?????

- ?????????????

- ?????? ?

- ?????????????

- 700 ??????

- ??????????????????

- ???????? ???????????????????????????

- ???????? ??????????

- ???????????????????????????

- ??????????(DPS)

- ??????

- ????????????????????

- ?????????????

- ?????????????

-

???

?60, 70,90&130??

-

?????

100 X 250, 150 X 300 ??

-

????????????

1,300 ?????

-

?????

1,870??

-

?????????

0 63 ??

-

?????

248 ??

-

??????

220??

-

???+/- :

??????150 ?

-

??????x??x??

0.02 ??

-

???

915 X 800 X 1,606 ?? 415 ?????

-

??????????????? ???????? ???????

-

PLC????

-

???????? ?????

-

????????

-

????

*以上是一般机极物理运作速度(只作参考作用) 真实速度可受印刷条件要求、油邕干固环境`上/落料效率寸饺头上/ 下速度寸饺头硬度及品质要求标准等客观环境因 素影响。