TURBO-90

Features

- Single color automatic pad printer

- Rigid aluminium cast machine frame

- Wide machine stand

- Platform in/out movement

- Pneumatic power machine operation

- Use sealed green ink cup (patented) set up

- Powered with AVC – Automatic viscosity control (patented)

- Able to use laser engraved Green plate, thin steel plate and

10 mm steel plate - Dead-on printing plate registration for

quick job change - PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke & speed adjustment

- Special functions: double ink / print cycles, dwell

and delay before print - Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing

ensure friction-free movement - High speed and smooth machine operations

-

Ink cup size (diameter) :

60, 70 & 90 mm

-

Printing plate size :

100 x 250 mm

-

Max. speed : (dry cycle)

1,100 I hr.

-

Pad compression :

1,178N

-

Pad cylinder :

dia50 x 125 mm

-

Pad carriage stroke (in/out) :

148 mm

-

Power :

110/220V 50/60Hz 65W

-

Air consumption :

118 litre/min. (approx.)

-

Accuracy +/- :

0.05 mm

-

Size (L x W x H) :

893 x 610 x 1,500 mm

-

Weight :

140 kg (approx.)

-

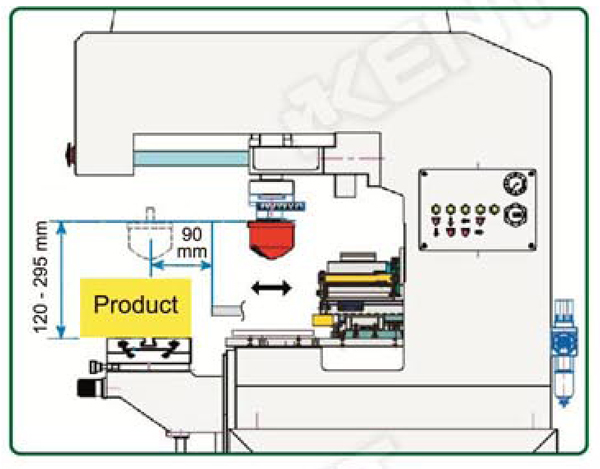

Small machine with wide stand for industrial applications such as golf balls, watch dials or small precision 1 color jobs.

Max. 80mm diameter printing area with auto pad clean.

-

PLC control touch screen panel

-

Auto pad clean

-

Platform in / out movement (Pad clean underneath)

-

AVC – Automatic viscosity control (patented)

-

Maximum space for product/image with auto pad clean function

*Please note that actual output may be affected by print requirement, ink drying condition, load,unload arrangement, pad stroke speed, pad hardness, production setup, product quality and production control.